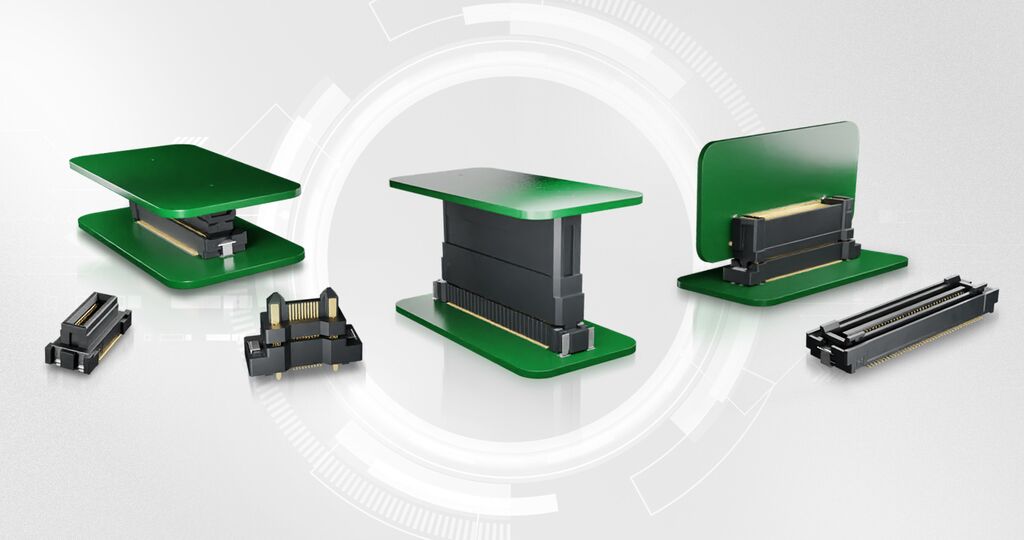

Flecto Floating Board to Board Connectors

Written by Ryan Smart

Modern electronic designs often incorporate multiple PCBs, whether as a way of decreasing design time by taking a modular approach or as a necessity to ensure the final solution fits the available space. Clearly, there needs to be an effective way of connecting these boards to distribute signals and power. While several methods exist, the use of board-to-board connectors has become widely adopted, with the demands of modern systems, meaning that often more than one connector is needed between PCBs.

Deploying multiple board-to-board connectors between a pair of boards necessitates very precise placement on the PCB, while the need for automated manufacturing demands placement at very high speeds. Unfortunately, with two or more connectors mating the same two PCBs, the level of placement accuracy may be outside the parameters of the manufacturing process. As even sub-millimeter misalignment can increase stress on the connectors, this is a problem with a potential to create quality, yield and field reliability issues.

Featuring spring-like terminals that allow them to move laterally and longitudinally and thus accommodate mis-alignment, ‘floating’ connectors provide an innovative solution to this problem. They can also contribute to improved connection integrity by absorbing shock or vibration during operational lifetime.

One of the most recent additions to the world of floating board-to-board connectors is our Flecto range. This comprehensive family of connectors offers a number of innovative features that allow for multiple connections between a pair of PCBs without placement accuracy issues.

Available in all-signal or mixed signal and power options, Flecto offers a broad range of options for contact pitches and number of contacts per connector, with mated mounting heights as low as 5.98mm. Products in the family support both parallel and right-angle interconnects, while additional support for accurate alignment and robust interconnects includes location pegs that eliminate movement during solder reflow and retention tabs.

The connectors that mix signal and power also offer through-board solderable posts to augment both location accuracy and mechanical strength, enhancing resistance to shocks.

With the Flecto family of floating connectors, designers are free to deploy multiple connectors per board pair without worrying about manufacturing compatibility. This can bring a number of benefits to the design. For example, sensitive analog circuitry can be segregated from noisy digital signals (such as system clocks), while time-sensitive traces can be kept as short as possible to avoid introducing latency problems.

For more information about Harwin’s Flecto Connectors, drop us a line.